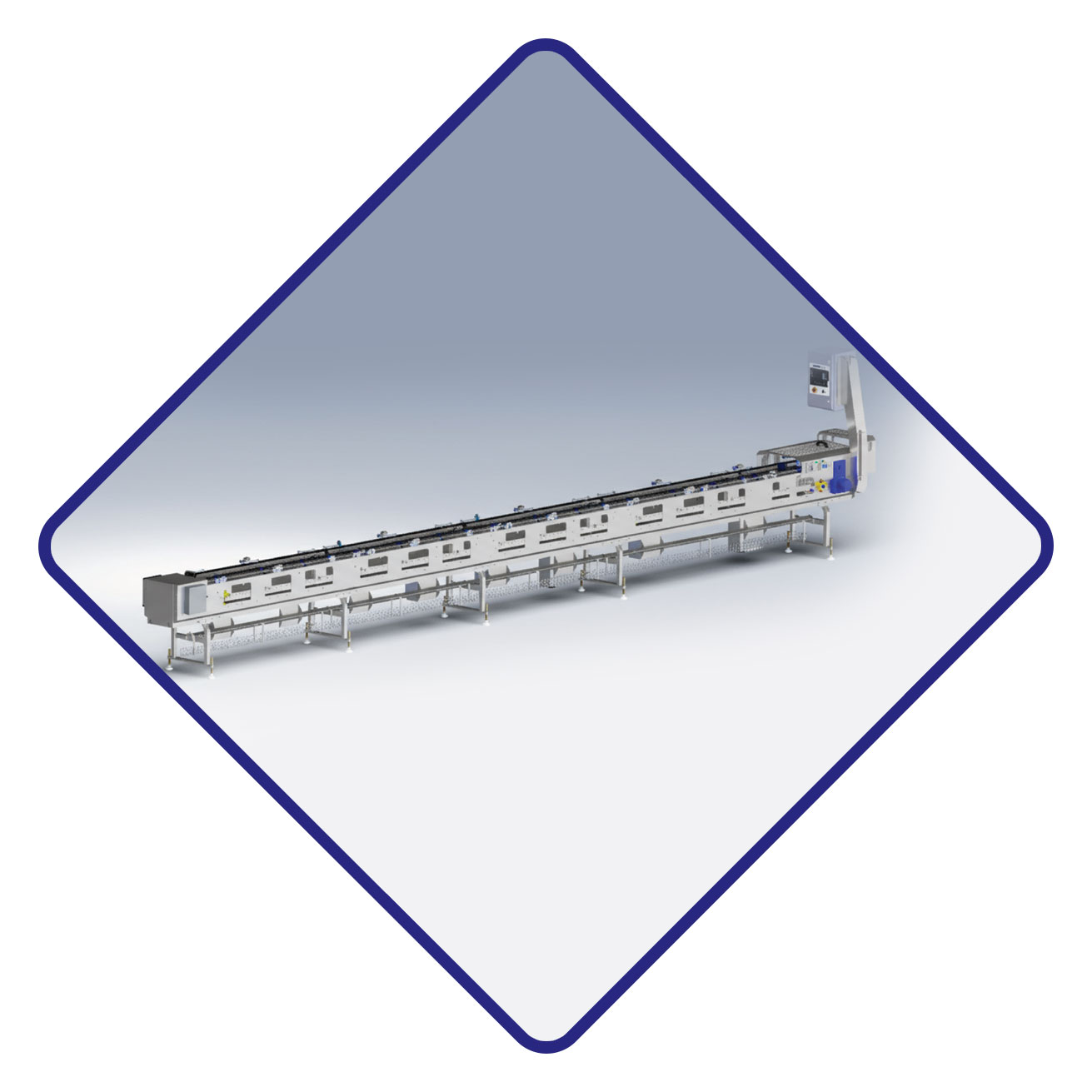

Standard Features Include:

• Hygienic Open Washdown Construction: 316L stainless steel frame with IP65 rating, featuring

smooth surfaces and minimal crevices for easy cleaning and full CIP (Clean-in-Place) compatibility.

• Recipe-Controlled Product Setup: Advanced HMI with recipe storage allowing instant changeover

between different product configurations with zero manual adjustment.

• Variable Chain Pitch Technology: Precision-adjustable chain pitch from 100mm to 500mm

accommodating specific tray sizes with +1mm positioning accuracy.

/ Full-Length Cantilevered Tray Guides: Self-adjusting guide system ensuring consistent tray

alignment throughout the entire conveyor length without manual intervention.

KPI tracking via encrypted wireless connection with 24/7 technical support access.

• Precision Indexing System: Servo-driven chain positioning with +0.5mm repeatability ensuring

consistent tray placement for downstream equipment.

Energy Efficient Design: Variable frequency drives and optimized motor selection reducing energy

• consumption by up to 35% compared to conventional systems.

MADE IN UK: Manufactured to British engineering standards with local support and rapid parts availability.

Optional Features Include:

Modular Length Configuration: Variable conveyor length from 3.36M to 18.36M using 1M and 2M

modules for custom production line layouts.

Integrated Electrical Outlets: Built-in power distribution for scales, sensors, and auxiliary

/ equipment with IP67-rated connections.

Wire Basket Cable Tray System: Organized cable management system with easy access for

• maintenance and modifications.

Integrated Tray De-nester: Seamlessly integrated automatic tray feeding system eliminating manual tray loading.

Multi-Lane Configuration: Expandable to 2, 3, or 4 lane configurations for increased throughput

capacity.

Vision Inspection Integration: Built-in mounting points and interfaces for quality control cameras

and rejection systems.

Product Counting & Tracking: RFID or barcode tracking system for complete product traceability

& throughout production.

• Emergency Stop Safety System: Comprehensive safety system with light curtains and emergency

stops positioned every 2 metres.

MPE is a UK based manufacturer of heat-sealing machinery mainly for applications within the food industry. We pride ourselves on providing a high level of customer satisfaction and offer a 24/7 backup service.

Our after sales service has helped to establish us as one of the market leaders in our field, offering you peace of mind and assurance that we are with you every step of the way.

Finland: Tel: +358(0)20 7995 888